Using DipAnalyst 2.0

DipAnalyst 2.0 is an application

software for kinematic analysis of rock slope failure potentials and

calculating factor of safety values against failure. It is developed for stereonet-based analysis as well as a new

quantitative kinematic analysis. The quantitative kinematic analysis,

instead of relying on representative values, considers all

discontinuities and their possible intersections to calculate failure

indices. Failure indices are calculated based on the ratio of the number

of discontinuities that cause plane failures or toppling failures or the

number of intersection lines that cause wedge failures to the total

number of discontinuities or intersection lines. The software compares

every dip direction/dip value with slope angle and friction angle to

evaluate its potential to cause plane or toppling failure. It also calculates

all potential intersection line plunge direction and amount for

wedge failure potential.

A higher index value for a given type of failure

indicates a greater chance for that type of failure to occur.

DipAnalyst 2.0 also allows a simple sensitivity analysis to

evaluate the change of failure indices with changing friction angles, slope angles,

and slope azimuths. The

quantitative approach for kinematic analysis can be easily interpreted

by professionals who are not familiar with the use of stereonets.

Using

DipAnalyst

New data can be entered directly onto the dip

direction and dip columns or can be imported from a .csv file, where the

first column contains dip direction and the next column contains dip

values. csv files can be created with Microsoft excel. Dip direction and

dip data can be saved as .csv file.

![]() Refresh

Refresh

The ‘Discontinuity Intersection Calculator’ tool

calculates the azimuths and plunges of all possible lines of

intersection between all possibly intersecting discontinuity planes.

Once executed, the other icons will be functional.

![]()

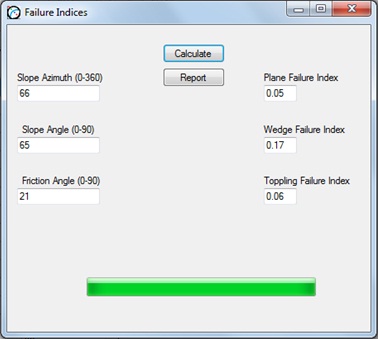

Failure indices are calculated based on the ratio

of the number of discontinuities that cause plane failures/toppling

failures or the number of intersection lines that cause wedge failures

to the total number of discontinuities or intersection lines. The

analysis would require valid slope azimuth, slope angle, and friction

angle data. A higher index value for a given type of failure indicates a

greater chance for that type of failure to occur. The ‘Calculate Failure

Indices’ tool calculates all three failure indices as shown below. The

resulting failure index can be exported as a text file by

clicking the ‘Report’ button.

Sensitivity Analysis

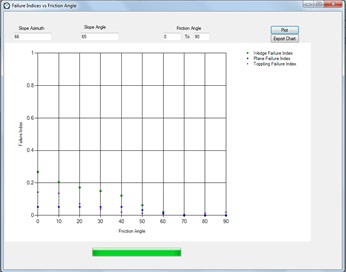

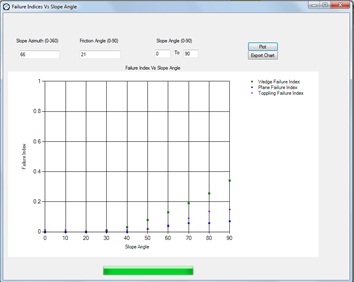

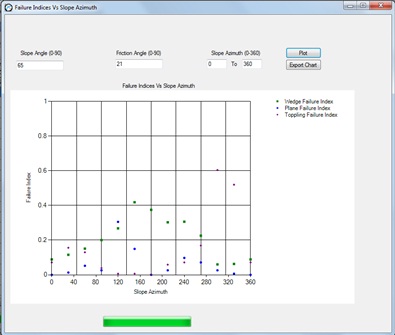

The change in failure indices as a result of

changing friction angle, slope angle, and slope azimuth is calculated.

The user can modify the range of friction angles, slope angles and slope

azimuths for which the sensitivity analysis can be performed. A scatter

plot for each sensitivity analysis can be drawn. The scatter plots can

be exported as a .bmp file by clicking the ‘Export Chart’ button.

Examples of sensitivity analyses are shown below.

![]() Failure

Index vs Friction Angle

Failure

Index vs Friction Angle

![]()

![]() Failure

Index vs Slope Azimuth

Failure

Index vs Slope Azimuth

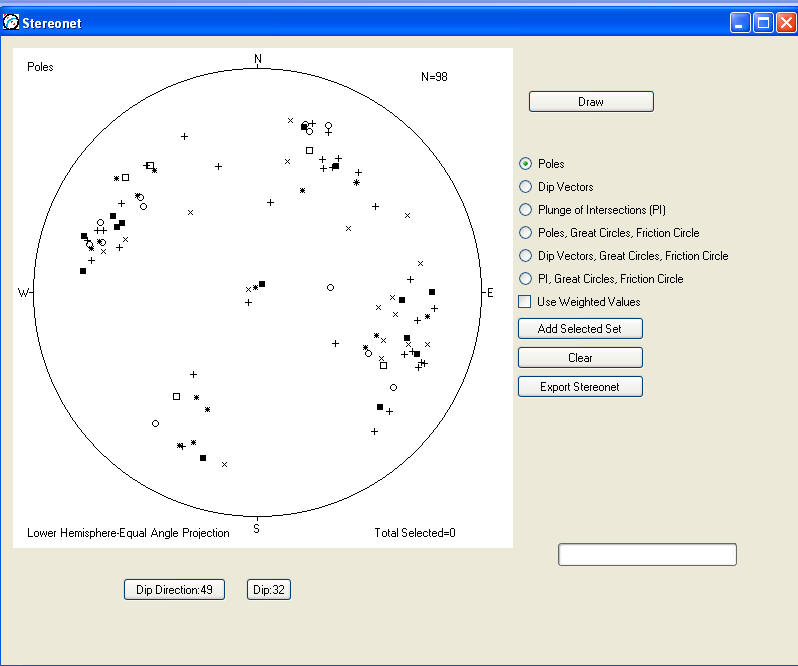

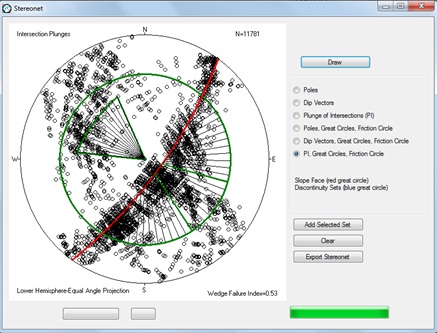

![]() Stereonet

Stereonet

The ‘Stereonet’ tool opens the ‘Stereonet’ window.

Poles, dip vectors and plunge of all possible intersection lines can be

plotted on the stereonet by clicking ‘Draw’ button. Based the symbol

codes entered in the data entry, dip vectors and poles may be

represented by different symbols.

The stereonet-based kinematic analysis for wedge failure can be performed based on plunges of all possibly intersecting discontinuity planes as shown below.

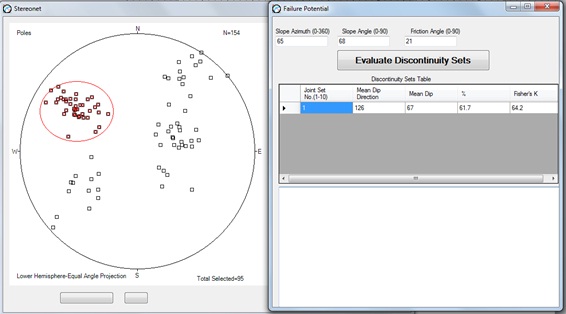

Selection of Discontinuity Sets

Cluster of discontinuities can be visually

identified from pole plot of discontinuities. Selection can be done by

left clicking at the upper left corner of the cluster set and holding

down the mouse until reaching the lower right corner of the cluster set.

The selected poles will be highlighted and the boundary around the

selected set will be visible. The mean dip direction, dip, percentage of

selected discontinuities, and Fisher’s K value can then be added into

discontinuity set table by clicking the ‘Add Selected Set’ button.

Clicking ‘Add Selected Set’ would also open the ‘Failure Potential’

window which contains the discontinuity set table.

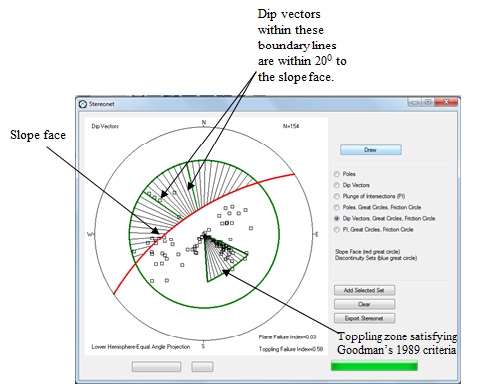

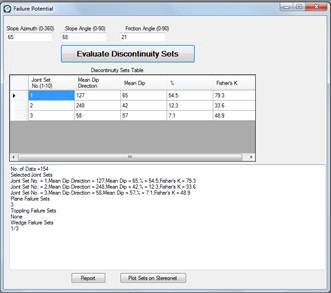

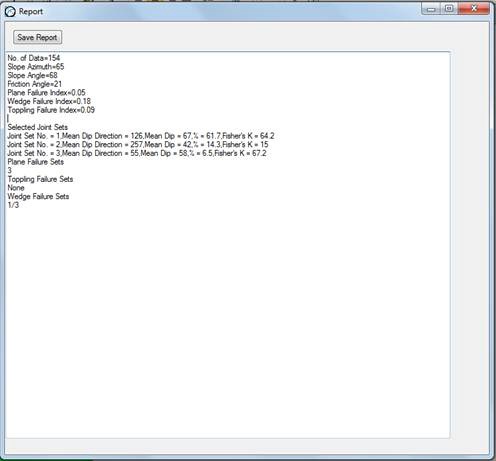

Evaluating Discontinuity Sets

The selected joint sets can be evaluated by

clicking the ‘Evaluate Discontinuity Sets’ button. The result is a text

report of the mean dip direction, mean dip, percentage of selected

discontinuities, and Fisher’s K values. It will indicate on which

discontinuity sets would cause plane and toppling failures as well as

which intersecting discontinuity cluster sets will cause wedge failures.

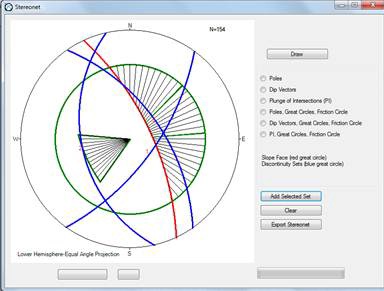

Great circles representing discontinuity sets,

slope face and the friction circle will be drawn by clicking ‘Plot Sets

on Stereonet’ button.

![]() Report

Report

The ‘Report’ tool will open a window with a text box

showing the result of failure indices calculation performed within the

‘Failure Indices’ window and discontinuity set evaluation within the

‘Failure Potential’ window. The ‘Report’ button should be clicked in the

‘Failure Indices’ window and/or ‘Failure Potential’ window for the

‘Report’ tool to record a report.

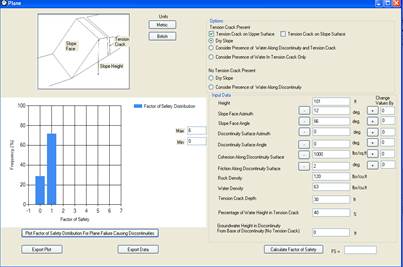

Plane

Plane

The ‘Plane Failure’ tool opens the window for plane

failure analysis. There are two options of analyses

that

DipAnalyst 2.0 provides. The ‘Calculate Factor of Safety’ button

performs the calculation of factor of safety for one discontinuity plane

based on the input data. The ‘Plot Factor of Safety Distribution For

Plane Failure Causing Discontinuities’ plots a histogram of distribution

of F.S values for all potentially plane failure-causing discontinuity

planes entered in the discontinuity entry page. It first identifies

discontinuities that have the potential for plane failure, calculates

their factor of safety values, and plots a histogram. The factor of

safety values can be exported.

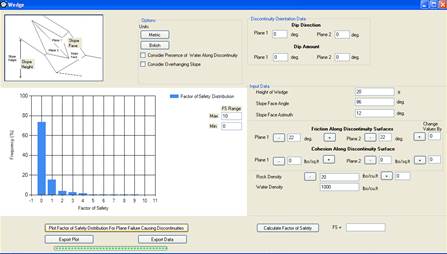

Wedge

Wedge

The ‘Wedge Failure’ tool opens the wedge failure analysis window.

Similar to plane failure analysis,

DipAnalyst 2.0 can

calculate factor of safety for a single wedge defined by a pair of

discontinuities as well as plot distribution of factor of safety values

for all possible intersecting discontinuities that potentially can lead

to wedge failures. The factor of safety values can be exported.